SUSTAINABLE STRETCH WRAP CAN SAVE YOU MONEY

Cut costs and meet your sustainability goals with a bio-assimilating stretch wrap.

WHY IT MATTERS

Sustainability and cost savings don’t have to be mutually exclusive. Using Vanish stretch wrap with a right-gauging assessment can help you reduce the amount of stretch wrap you consume, saving you money and cutting plastic waste. The Vanish film that you do use will bio-assimilate back into the earth, leaving behind no microplastics.

BY THE NUMBERS

Save an average of 6% on your stretch wrap spend and reduce your plastic consumption by 12% with Vanish and a right-gauging assessment.

MEET YOUR SUSTAINABILITY GOALS WITH VANISH

Eliminate plastic waste by pairing Vanish with a right-gauging assessment: Combining Vanish stretch wrap and a right-gauging assessment is a simple and powerful method to eliminate plastic waste in two ways:

- Reduce stretch wrap consumption: A right-gauging assessment optimizes the amount of film that you are using to wrap each pallet, which often means reducing the amount of film you use.

- Let the stretch wrap you do use bio-assimilate: Vanish stretch wrap is designed to return to the earth via bio-assimilation after its functional lifespan.

How the bio-assimilation process works: Vanish has a guaranteed functional lifespan of two years, after which the bio-assimilation process begins. An added ingredient called SPTek Eclipse enables microorganisms to break down the plastic in any environment, including the landfill. It will fully return to nature within 6-24 months, leaving behind no microplastics or toxins.

SAVE MONEY BY OPTIMIZING STRETCH WRAP USE

Buy less stretch wrap by cutting consumption: Companies that undergo a right-gauging assessment reduce their stretch wrap consumption by an average of 12%. This comes from finding the ideal film, gauge, and machine settings needed to maximize load containment, while minimizing excess film use. Direct cost savings come by simply buying less stretch wrap.

Total cost per pallet decreases by an average of 6% when conducting a right-gauging assessment with Vanish. While Vanish film costs 7% more than non-sustainable film, using less of it results in an average of 6% cost savings per pallet wrapped.

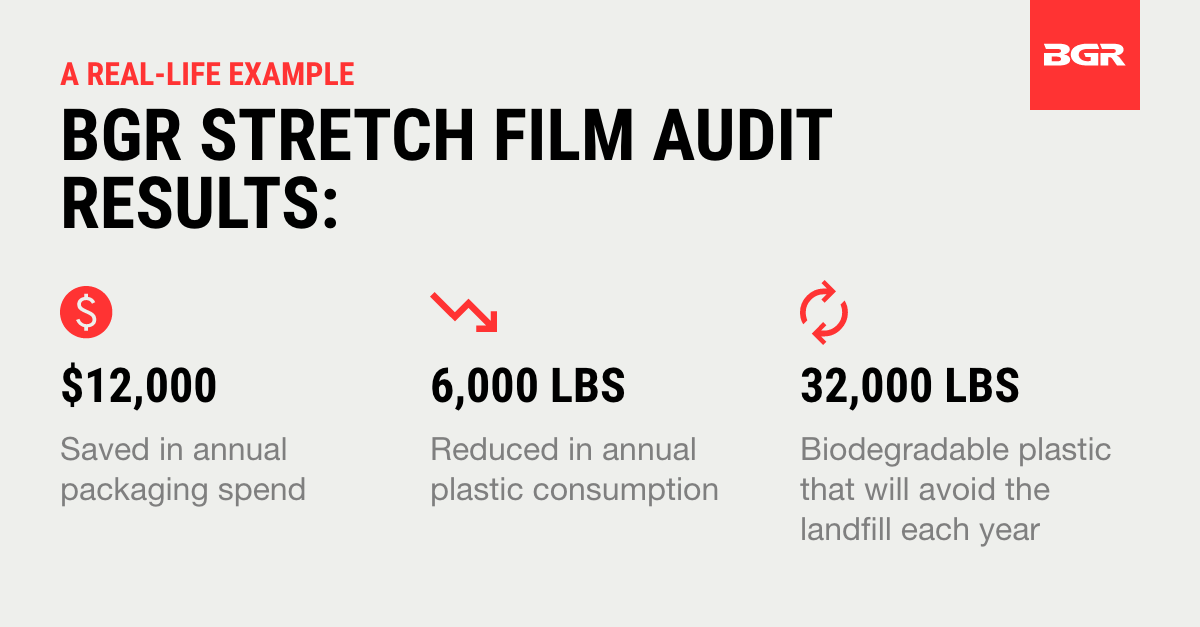

A REAL-LIFE EXAMPLE

Through a right-gauging assessment for Vanish, BGR recently helped a customer save money and meet two of their sustainability goals: 1) reducing total packaging usage and 2) replacing conventional plastics with compostable or bio-assimilating packaging

The results:

- $12,000 reduction from their packaging spend

- 6,000 pounds of reduction plastic consumption annually

- 32,000 pounds of plastic that will biodegrade out of the landfill annually

SUSTAINABLE STRETCH WRAP WORKS GREAT FOR YOUR PRODUCTION TEAM

- Works for a variety of users: Vanish comes in both machine and hand wrap options, with numerous gauges available. The machine wrap is compatible with any high-speed automatic stretch wrapper. When switching to Vanish, you won’t need to make any changes to your wrapping methods.

- Protect your products during shipping: Vanish excels at what it is ultimately designed to do: protect your products during shipping. It provides excellent load-containment and puncture resistance, keeping your products safe in transit.

- Get more space and less damage: Vanish has single-sided cling, which keeps wrapped pallets from sticking together. This allows you to pack trucks and warehouse racks tightly without worrying about the film sticking, tearing, or pallets collapsing.

THE BOTTOM LINE:

Sustainable stretch film can cut costs and plastic waste.

Sigma’s Vanish stretch wrap is an affordable and high-performing film that will help you meet your sustainable packaging goals. Using this stretch wrap in conjunction with a right-gauging assessment is a way to double down on sustainability. It reduces the amount of film used and allows the rest to break down naturally in the waste stream. The end result is that you save money on packaging and attain your sustainability objectives.

READY TO MEET YOUR SUSTAINABILITY GOALS?

FAQS

Bio-assimilation is the final stage of biodegradation. It means the plastic is broken down to a molecular weight that living organisms can consume. At the end of the bio-assimilation process, all that is left is water, biomass, and a bit of carbon dioxide.

Bio-assimilation products like Vanish go a step further than most bio-degradable products. Many biodegradable products break down over an unspecified time period, leaving behind microplastics. Vanish goes a step beyond this, breaking down completely within 6-24 months, leaving behind no microplastics.

Vanish will fully bio-assimilate in any environment. This could mean in the landfill, in the environment, or even in the ocean. However, this does not mean it is ok to litter the film.

No, the film will not bio-assimilate until 2 years after its production. The film will already have been used and disposed of by the time the bio-assimilation process beings. Once the bio-assimilation process begins, it will be completely returned to nature within 6-24 months.

The base formulations for Vanish are Sigma Summit Machine Film and Sigma Steel Hand Film. Vanish has identical performance attributes as these films – the bio-assimilating additive has no effect on the film’s performance.

Yes, Vanish is recyclable in a store drop-off bin. While most stretch films are technically recyclable, the vast majority end up in a landfill because films require special recycling that is not available for your normal “curbside” recycle service. Vanish’s sustainable value lies in the fact that if the film is not recycled, it will bio-assimilate. But the film can still be recycled if it is sent to the right recycling center.